Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

In early 2025, the world’s attention turned to a pivotal moment in the automotive industry: the record‑breaking launch of new electric vehicle (EV) models by all major automakers, spurred by both breakthrough battery technology and a sweeping regulatory push toward zero emissions. Bloomberg reported that electric sales grew by 32% last year, a figure above all historical forecasts. This surge, driven by the introduction of Tesla’s 4680 battery cells and equivalent innovations from Rivian, Volkswagen, and Hyundai, poses a critical challenge for the powertrains that bring those vehicles to life. Enter the gear motor, or reducer motor—a compact, high‑torque marvel that is now at the heart of the EV revolution.

The 2025 trend is simple yet profound: governments worldwide are tightening emissions standards, and consumers are demanding cleaner, more efficient transport options. Europe’s “Fit for 55” package, China’s Phase‑3 green‑energy strategy, and the United States’ new federal EV incentive legislation have all converged on a common goal—significantly lower CO₂ emissions by 2035. For automakers, this means integrating batteries with lower pack weight, producing cars that can accelerate faster and travel farther on a single charge, all while keeping production costs competitive.

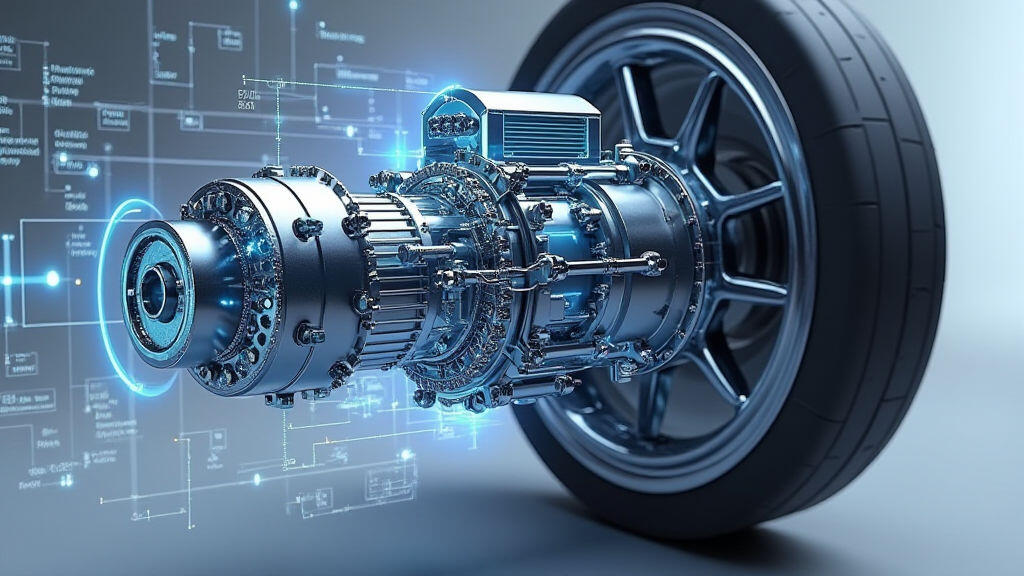

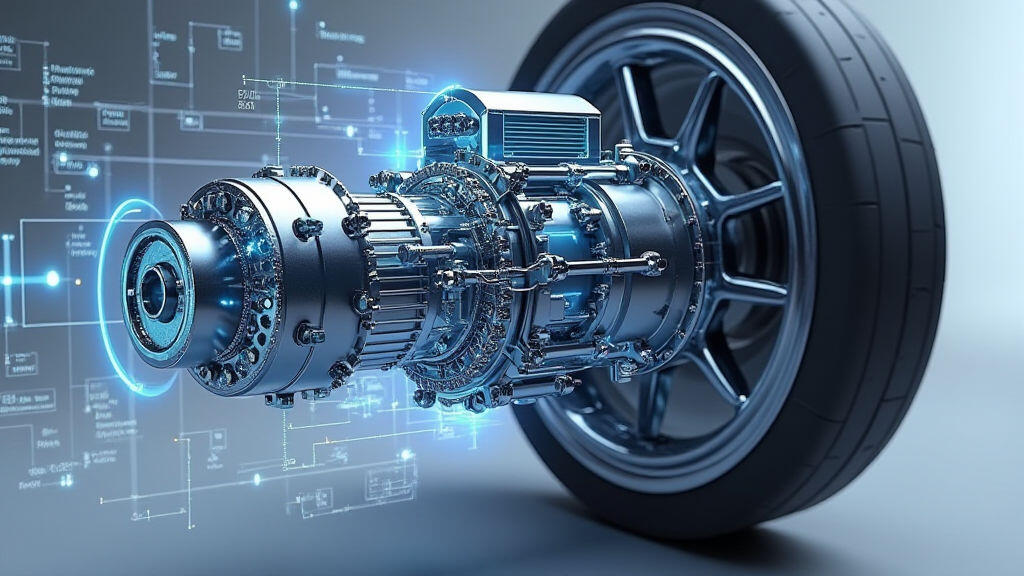

At the core of every EV powertrain lies a power conversion system that translates electrical energy into mechanical torque. Traditional internal combustion engines rely on a large gearbox to modulate torque across variable speeds. In contrast, electric motors can produce maximum torque from zero RPM, rendering a multi‑speed gearbox seemingly redundant. However, the practical realities of motor design—size, weight, cooling, and efficiency—necessitate a different approach. Gear motors combine a permanent‑magnet or induction motor with a gearbox, creating a single, compact unit that delivers the ideal torque curve while reducing overall weight and complexity.

Why are gear motors indispensable for the 2025 EV boom? First, modern battery cells deliver higher voltage but lower current per cell. By reducing the shaft speed of the motor using an integrated gearbox, gear motors allow high‑torque output without exceeding the electrical limits of the battery. This technology is a key enabler of the “ultra‑fast charging” promises by automakers and charging networks, as it helps keep motor temperatures manageable while sustaining high power output.

Second, gear motors drastically shrink the packaging footprint. A truck‑size gear motor (120 N·m torque rating) can fit in the space previously occupied by an entire gearbox assembly. For compact urban cars and sub‑compact SUVs—segment choices that are expected to explode in 2025—such space savings are vital for both passenger volume and battery placement flexibility.

Finally, gear motors improve the overall energy efficiency of the vehicle. Because the motor can operate closer to its optimal power factor and drivetrain losses are minimized, the vehicle’s range per charge increases. Given that range anxiety remains a top consumer concern, even a 3–5 % improvement in efficiency translates into a measurable competitive advantage.

Industry analysts predict that the global gear motor demand will climb by 18% annually through 2030, driven largely by the EV sector. Manufacturers are responding with advanced features—lightweight materials such as titanium alloys, high‑temperature insulation for permanent magnets, and surface‑mounted bearing technology—to ensure reliability, especially in harsh automotive environments. Supplier alliances are forming: European manufacturers partnering with Asian motor specialists aim to secure a steady supply chain amidst rising geopolitical scrutiny over critical technology.

In new product lines, gear motors are increasingly adapted to hybrid architectures as well. The emerging “flare‑toward electric” approach in Ford’s new Mustang Mach-E and Audi’s EQS models, for example, uses gear motors to seamlessly blend electric-only segments with traditional engine operation, providing smooth acceleration across power sources.

The regulatory framework itself indirectly fuels the gear motor market. Mandatory “EV Packaging Requirements” set by the European Union stipulate weight and dimension limits for the overall propulsion system. Gear motors satisfy these constraints by lowering mass per unit torque, thereby allowing automakers to keep battery packs within the mandated limits. Likewise, the United States’ “Build America” procurement guidelines encourage the sourcing of critical components, such as high‑torque motors, from domestic suppliers, prompting an uptick in U.S. gear motor manufacturing plant investments.

However, supply chain resiliency remains a pressing issue. The 2023–2024 global semiconductor shortages, along with restrictions on rare‑earth materials from major suppliers in China, have highlighted the vulnerability of gear motor production. To mitigate this risk, automotive OEMs are diversifying their supplier base, investing in additive manufacturing of motor housings, and collaborating with research institutions to develop non‑rare‑earth permanent magnet solutions.

Looking forward, gear motors are poised to be the cornerstone of emerging EV applications beyond passenger cars. Autonomous delivery robots, electric cargo ships, and even next‑generation “flights” for electric air taxis require precise torque control in a compact form factor—exactly the niche that gear motors fill. Furthermore, the integration of smart‑sensing technologies into gear motors can facilitate real‑time diagnostics, predictive maintenance, and adaptive control, opening avenues for vehicle‑to‑grid (V2G) interactions that power local grids during peak demand.

The 2025 electric vehicle surge is a seismic shift that redefines every component in the automotive supply chain. Gear motors, with their integrated gearbox, compactness, and superior torque efficiency, are no longer optional but essential. As governments tighten emissions targets, battery technologies advance, and consumers demand higher performance and longer ranges, the demand for reliable, high‑performance gear motors will only grow.

Whether powering the sleek electric sedans of tomorrow or the autonomous delivery drones that will pepper city skies, the gear motor’s role is that of a silent engine master—delivering power efficiently, precisely, and sustainably. The future of clean mobility hinges on its evolution, and the industry’s investment in gear motor technology today will decide whether the electrified roads of 2035 are not only reachable but also robust and reliable.

Leave A Reply

Your email address will not be published. Required fiels are marked